Version

Available in lengths up to

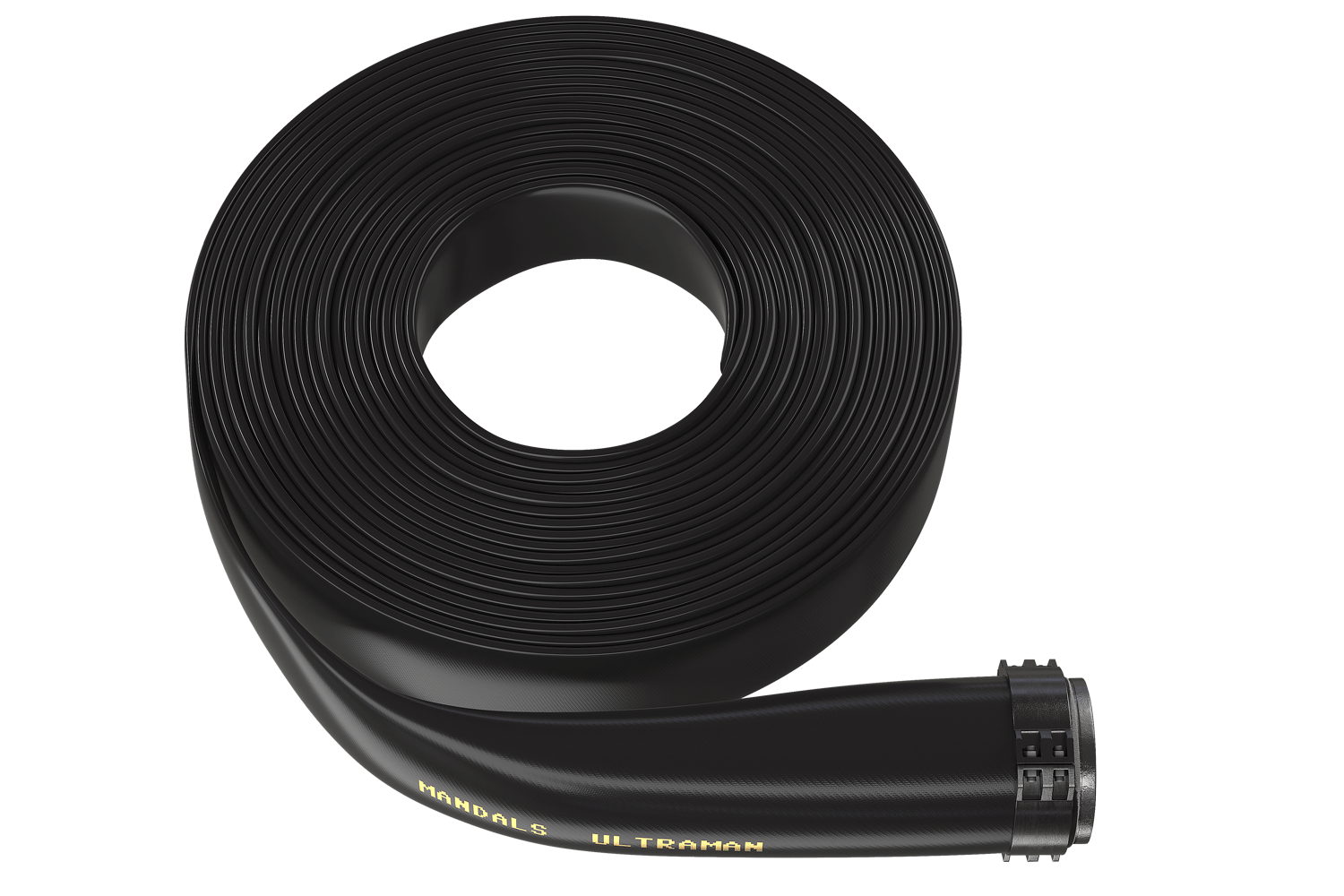

Durable and Lightweight All-Round Hose

Ultraman is designed as a lightweight transfer hose, meant for all-around use in mining, energy, and agriculture. Easy handling and a long service life make it very cost-effective.

Ultraman differs from our other high-volume transfer hoses, Ultraman HVT and Superman HVT in that it is a lighter construction and comes only in dimensions up to 7’’.

Made to Perform

For many of our customers, Ultraman is known as the “little brother” to Ultraman HVT. Designed as a multipurpose transfer hose it is ideal for a variety of industries. The high operational pressure and compact, lightweight storage is one of the reasons that Ultraman is so popular. The hose is available in a range of dimensions, from 2 1/2″ to 7″. For bigger dimensions, we do recommend Ultraman HVT.

Explore Ultraman

Ultraman

Ultraman

Product Specifications

Primary Uses & Applications

- Dewatering of open pit mines

- Bypass line for sewage

- Bypass line for slurry

- Feeder hose for irrigation

- Draghose in smaller umbilical systems

Color Options

- Black (standard)

Lengths and Diameters

We offer a range of diameters and lengths for this hose, depending on the version. The diameters range from 65mm to 178mm, and for some diameters, the hose can be delivered in lengths up to 500m.*

*Longer lengths are available on special request for certain diameters.

Operating Temperature

The hose has been developed to perform in different weather and environments, with an operating temperature from -50°C to + 75 °C ( -58°F to +167°F) for pure water.

Ultraman

| INTERNAL DIAMETER | WALL THICKNESS | WEIGHT | BURST PRESSURE | TENSILE STRENGTH | |||||

| Inch | mm | Inch | mm | Lbs / Ft | Kg / m | Psl | Bar | x 1000 Lbs | Tons |

| 2 1/2 | 65.0 + 2.0 | 0.11 | 2.8 | 0.44 | 0.66 | 810 | 56 | 14.3 | 6.5 |

| 3 | 76.0 + 2.0 | 0.11 | 2.9 | 0.56 | 0.84 | 725 | 50 | 17.4 | 7.9 |

| 3 1/2 | 90.0 + 2.0 | 0.12 | 3.0 | 0.66 | 0.98 | 620 | 43 | 20.0 | 9.1 |

| 4 | 102.0 + 2.5 | 0.13 | 3.2 | 0.81 | 1.20 | 610 | 42 | 22.2 | 10.1 |

| 4 1/2 | 114.0 + 2.5 | 0.13 | 3.2 | 0.93 | 1.39 | 535 | 37 | 23.8 | 10.8 |

| 5 | 127.0 + 2.5 | 0.13 | 3.3 | 1.02 | 1.52 | 505 | 35 | 26.4 | 12.0 |

| 6 | 152.0 + 3.0 | 0.13 | 3.3 | 1.16 | 1.73 | 435 | 30 | 32.8 | 14.9 |

| 7 | 178.0 + 3.0 | 0.13 | 3.4 | 1.38 | 2.05 | 390 | 27 | 37.6 | 17.1 |

Note:Safety BP/WP is 2:1 (50%). For all non-hazard and/or non-flammable liquids.

Agriculture Catalog

Want more in-depth knowledge about our lay-flat hoses for drag, supply, and irrigation lines? Maybe you want to know more about the difference between drag hoses and slurry tanks? Well, we got you covered in our agriculture catalog.

Mining Catalog

Want more in-depth knowledge about our lay-flat hoses for water management systems? Well, we got you covered in our mining catalog.

Let's Talk About Mandals Ultraman

Our dedicated Sales Managers are ready to cater to your needs and find proper solutions for your business.

Regardless of where you are in the world – we got you covered. Get in touch today.

Stig Seglem

Sales Manager - Asia, Oceania & Middle East

Global Sales Manager - Pipe Rehabilitation

+47 38 27 24 00

[email protected]

Address

Nordre Banegate 26,

4515 Mandal,

Norway