Versions

Available in lengths up to

Safe Rehabilitation of Drinking Water Lines

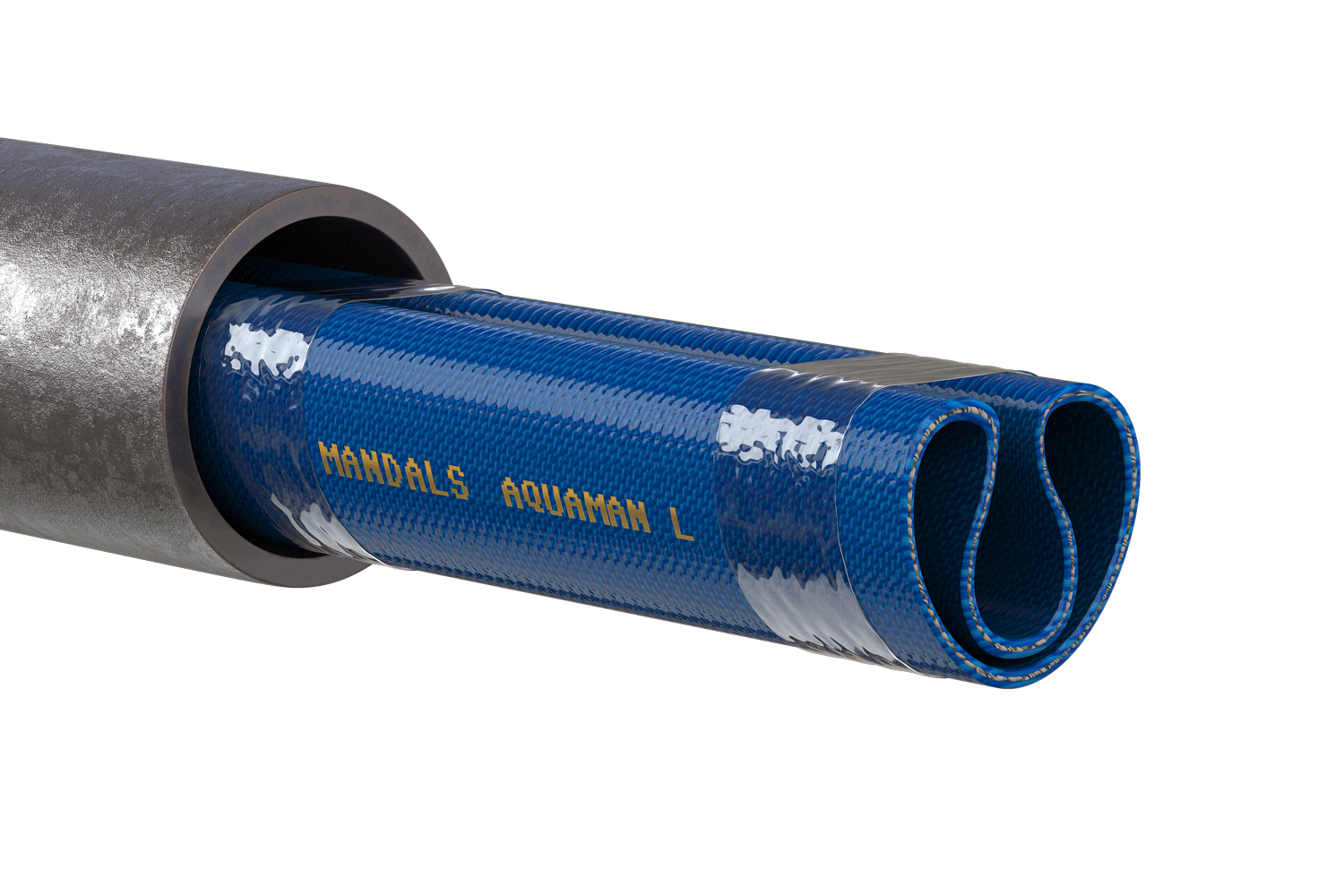

Mandals Aquaman L & M is designed to effectively rehabilitate drinking water lines in Low and Medium pressure systems. The liner is drinking water approved, with good hydrolysis and microbiological resistance, and is designed to have a lifespan of more than 50 years.

A Smarter Way

Countries throughout the world suffer from contamination and loss of drinking water due to old pipes leaking and deteriorating. With an average of 26% water loss in Europe and North America in 2020, this is a rising problem that needs to be addressed. In the US alone, it is said that approximately every two minutes, a water main breaks, and the potential water loss is estimated to be six billion gallons annually. We have developed Mandals Aquaman L & M specifically to address this problem and provide an easy-to-handle, effective solution to rehabilitate these pipes.

Explore Mandals Aquaman L & M

Mandals Aquaman L & M

Mandals Aquaman L & M

Production and Design

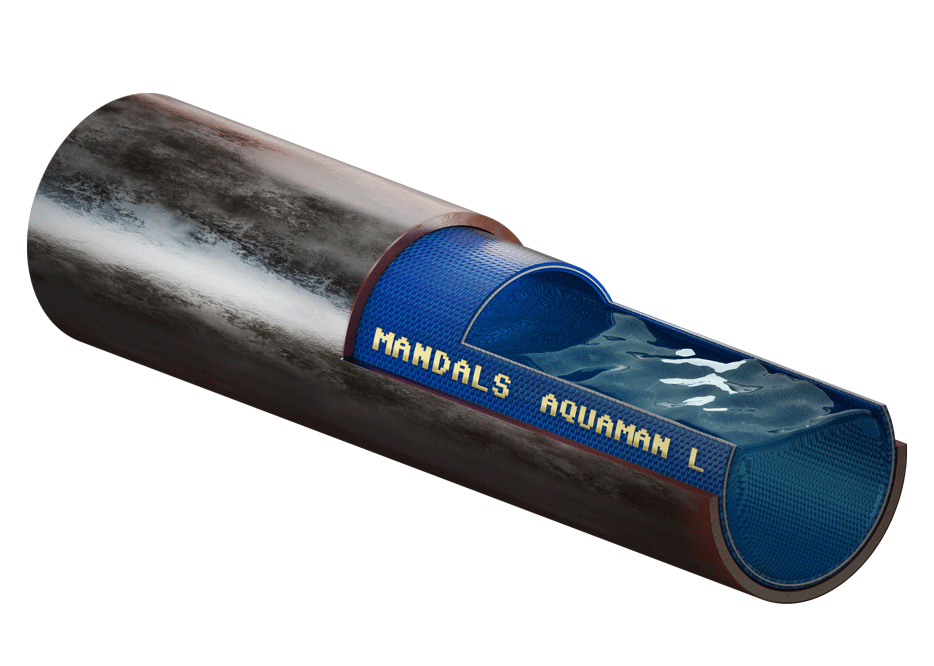

Mandals Aquaman L & M is a semi-structural, stand-alone liner that will ensure continual fluid supply even if the host pipe should break. In other words, the liner will handle all the pressure, while the pipe structure will help it not collapse.

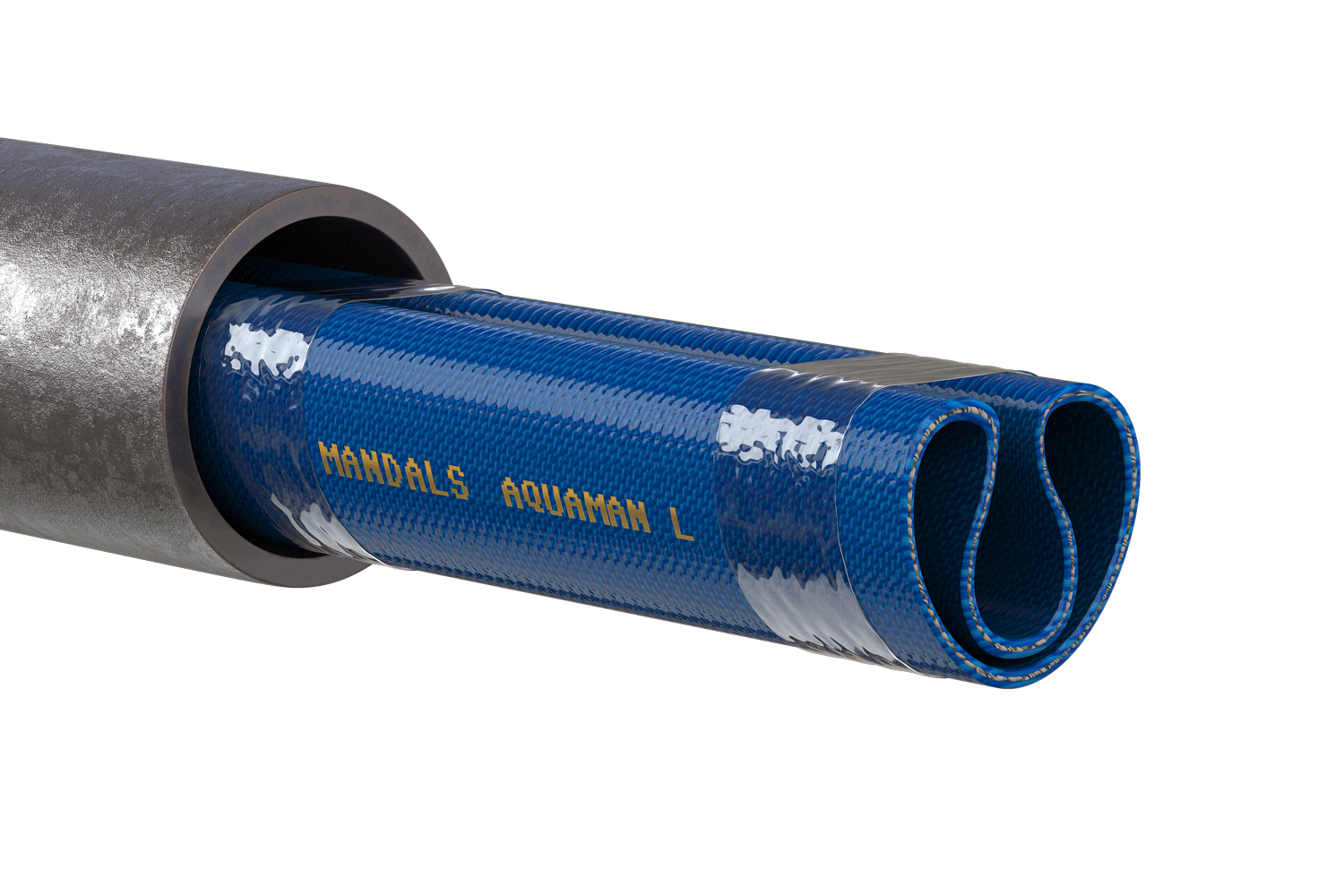

The “extrusion through the weave” production technology gives excellent bonding between the cover and lining and firmly encapsulates the circular woven textile reinforcement.

It consists of a thermoplastic polyurethane (TPU) with excellent wear & tear properties, outstanding hydrolysis resistance, and resistance against microbiological attack.

The liner is leak-proof, tested, packed, and delivered in a “U” -shape.

Installation Process

Before installation, a regular cleaning procedure is required for the host pipe and the condition is controlled by CCTV inspection.

The liner is pulled through the host pipe using a wire winch, e.g. and can be installed in pipelines with bends and pipe diameter variations. The number of bends and sharpness (bend angle and R/D – ratio) will impact the installation’s maximum section lengths.

No steaming or other means of curing is required. Operating at maximum working pressure, the outer diameter of the liner will be about 10mm less than the inner diameter of the rehabilitated pipe.

Product Specifications

Primary Uses & Applications

- Safe trenchless rehabilitation of drinking water lines

Color Options

- Blue (standard)

Lengths and Diameters

Aquaman L

We offer a range of diameters and lengths for this liner, depending on the nominal pipe diameter. The diameters range from DN20mm to DN350mm.

- DN20-DN150 can be delivered in lengths up to 600m

- DN200-DN350 can be delivered in lengths up to 400m

Aquaman M

We offer a range of diameters and lengths for this liner, depending on the nominal pipe diameter. The diameters range from DN150mm to DN350mm.

- DN150-DN350 can be delivered in lengths up to 400m

Section lengths will depend on

- Number of bends: More bend => Higher friction => Higher pull-force.

- Bend angle and R/D ratio: Sharp bends (critical low R/D ratio) => Higher friction and greater risk of damage to the hose during Pull-in. Can be dampened with good lubrication (silicone oil/cooking oil etc.) on the hose. Increased risk of “kinking” of the hose within the bend and reduced flow.

Operating Temperature

The maximum recommended operating temperature is +23°C (73°F)

Lifetime Expectancy

Service Lifetime will depend on several important factors such as proper and correct installation, condition of the existing pipe, dosage of and type of disinfectants used.

Chemicals and pH Range

The drinking water is normally stabilized as to chemical reactivity and microorganisms contents. The recommended pH range is 4-9.

Valid Certificates

Aquaman M

North and South America

Germany

Australia and New Zealand

Valid Certificates

Aquaman L

North and South America

Germany

Australia and New Zealand

Mandals Aquaman L

| ART. NR.: | NOM. PIPE

SIZE DN |

INNER DIAMETER | WALL THICKNESS | NOMINAL WEIGHT | MAX. WORKING PRESSURE (1) |

BURST PRESSURE | ACTUAL TOTAL TENSILE STRENGTH |

|||||||

| – | inch | mm | inch | mm | inch | mm | lbs/ft | kg/m | psi | bar | psi | bar | lbs x 1000 | kg x 1000 |

| AQL020 | 3/4 | 20 | 0.59 | 15.0 | 0.05 | 1.2 | 0.05 | 0.07 | 260 | 18 | 650 | 45 | 1.2 | 0.5 |

| AQL025 | 1 | 25 | 0.80 | 19.8 | 0.05 | 1.2 | 0.06 | 0.09 | 260 | 18 | 650 | 45 | 1.6 | 0.7 |

| AQL065 | 2 ½ | 65 | 2.00 | 51.0 | 0.11 | 2.8 | 0,33 | 0.52 | 320 | 22 | 800 | 55 | 6.4 | 2.9 |

| AQL080 | 3 | 80 | 2.50 | 65.0 | 0.12 | 3.0 | 0.41 | 0.70 | 260 | 18 | 650 | 45 | 8.6 | 3.9 |

| AQL100 | 4 | 100 | 3.00 | 76.0 | 0.13 | 3.3 | 0.57 | 0.85 | 260 | 18 | 650 | 45 | 11.9 | 5.4 |

| AQL125 | 5 | 125 | 4.00 | 102.0 | 0.13 | 3.4 | 0.85 | 1.28 | 245 | 17 | 610 | 42 | 16.1 | 7.3 |

| AQL150 | 6 | 150 | 4.50 | 113.0 | 0.14 | 3.6 | 1.03 | 1.54 | 245 | 17 | 610 | 42 | 22.9 | 10.3 |

| AQL200 | 8 | 200 | 6.10 | 154.0 | 0.16 | 4,0 | 1.63 | 2.45 | 245 | 17 | 610 | 42 | 45.9 | 20.7 |

| AQL250 | 10 | 250 | 7.60 | 193.0 | 0.17 | 4.2 | 2.09 | 3.14 | 245 | 17 | 610 | 42 | 57.5 | 25.9 |

| AQL300 | 12 | 300 | 8.90 | 227.0 | 0.17 | 4.4 | 2.47 | 3.70 | 200 | 14 | 490 | 35 | 66.4 | 29.9 |

| AQL350 | 14 | 350 | 10.70 | 274.0 | 0.18 | 4.6 | 3.22 | 4.80 | 175 | 12 | 435 | 30 | 78.8 | 35.5 |

Note: (1) Values are for hose only; allowed working pressure can not exceed coupling pressure rating. For questions about chemical resistance please check mandals.com/support.

Mandals Aquaman M

| ART. NR.: | NOM. PIPE SIZE DN |

INNER DIAMETER | WALL THICKNESS | NOMINAL WEIGHT | MOP (1) | BURST PRESSURE | ACTUAL TOTAL TENSILE STRENGTH | |||||||

| – | inch | mm | inch | mm | inch | mm | lbs/ft | kg/m | psi | bar | psi | bar | x1000 lbs | x1000 kg |

| AQM150 | 6 | 150 | 4.84 | 123.0 | 0.18 | 4.6 | 1.40 | 2.10 | 812 | 56 | 2030 | 140 | 100 | 45 |

| AQM200 | 8 | 200 | 6.57 | 154.0 | 0.18 | 4.6 | 1.93 | 2.9 | 580 | 40 | 1450 | 100 | 137 | 62 |

| AQM250 | 10 | 250 | 8.35 | 212.0 | 0.19 | 4.8 | 2.51 | 3.8 | 435 | 30 | 1088 | 75 | 172 | 77 |

| AQM300 | 12 | 300 | 10.16 | 258.0 | 0.19 | 4.8 | 3.00 | 4.5 | 377 | 26 | 928 | 64 | 211 | 95 |

| AQM350 | 14 | 350 | 11.70 | 297.0 | 0.20 | 5.0 | 3.56 | 5.3 | 290 | 20 | 725 | 50 | 242 | 109 |

Note: (1) The sharpest bend angle and corresponding R/D ratio of the pipeline system will impact and set the Maximum Operating Pressure (MOP). A 45° bend (R/D = 5.5) will entail a 45% reduction of MOP of the rehabilitated pipeline system. (2) Service Lifetime will depend on important factors such as proper and correct installation, condition of the existing pipe, dosage of and type of disinfectants used. 3Tolerances according to ASTM F3708-25. For questions about chemical resistance please check mandals.com/support.

Pipe Rehabilitation Catalog

Want more in-depth knowledge about our liners for pipe rehabilitation? Well, we got you covered in our pipe rehabilitation catalog.

Let's Talk About Mandals Aquaman L & M

Our dedicated Sales Managers are ready to cater to your needs and find proper solutions for your business.

Regardless of where you are in the world – we got you covered. Get in touch today.

Address

Nordre Banegate 26,

4515 Mandal,

Norway

Phone

Follow Us

Contact Us

"*" indicates required fields