Version

Available in lengths up to

The Lightweight Firehose

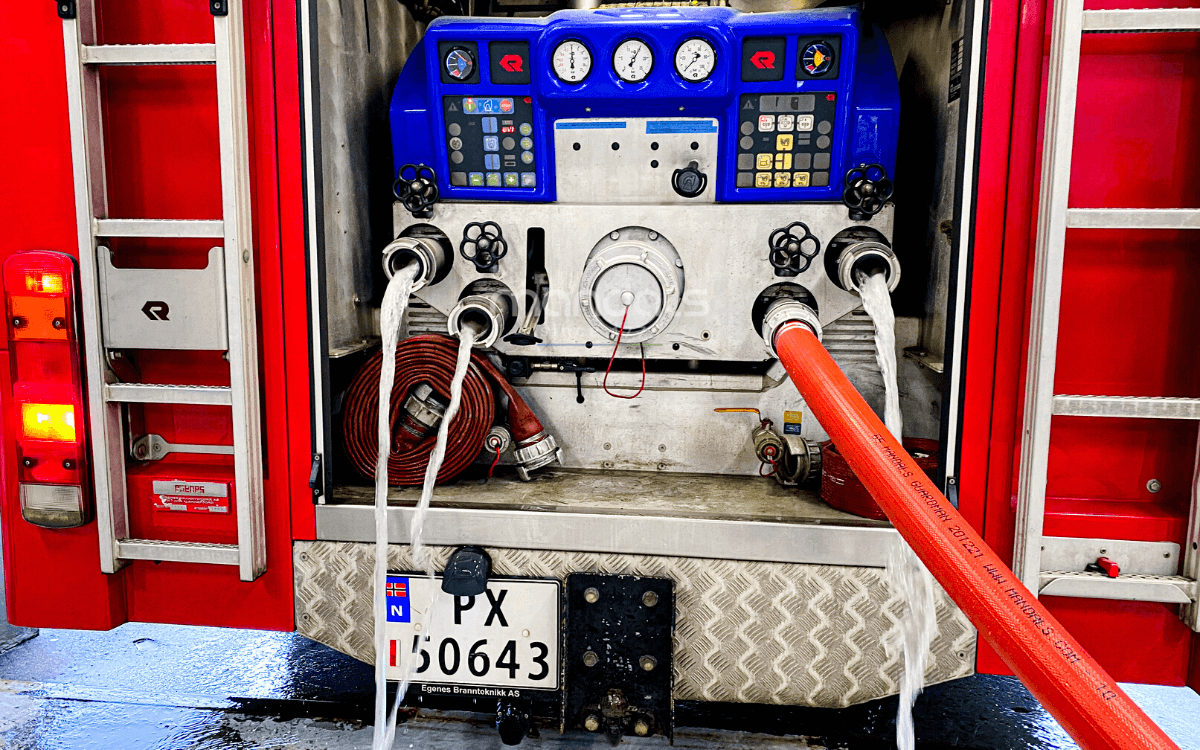

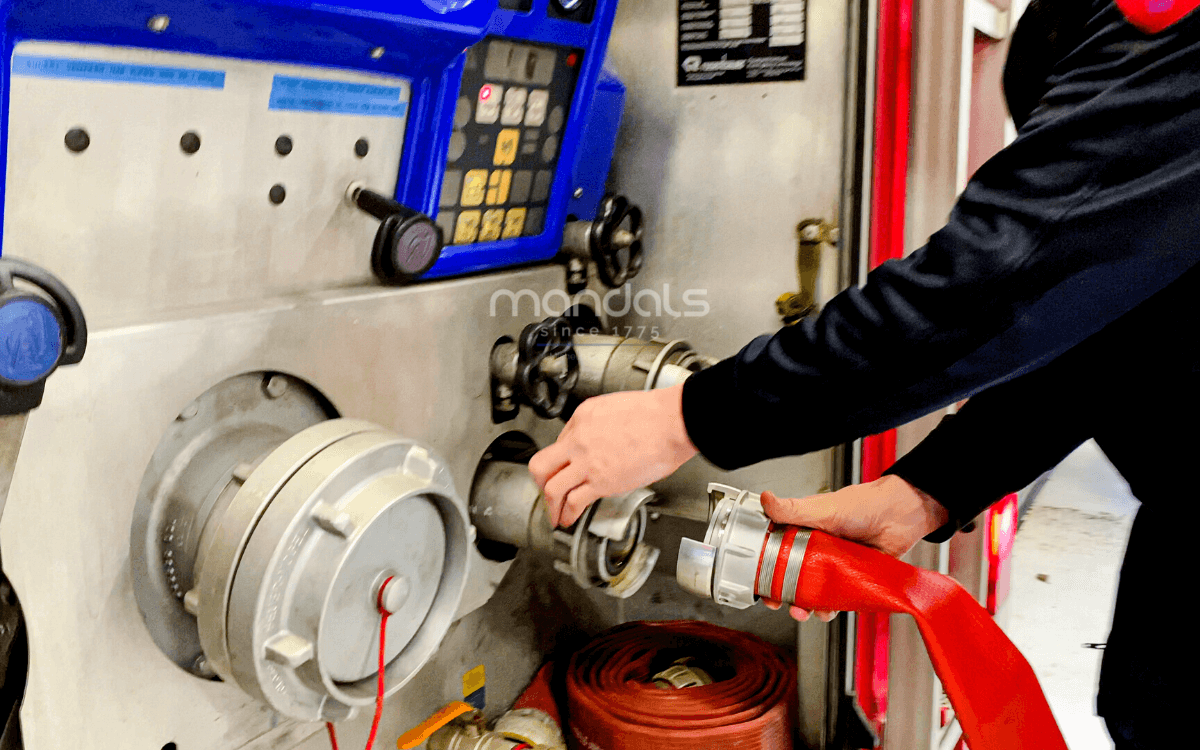

Guardman is our number one firehose, and has set the standard globally for firehoses since it’s origin in the 1960’s. It was originally known as Armtex, and it’s categorized as a type 3 firehose according to the British Standard, which means it has an external elastomeric coating.

Made to Last

The unique hose construction by the circular weave, covered and lined with the nitrile/PVC rubber gives at least 5 times longer lifetime compared to traditional textile hoses. Guardman was developed to meet the need for a fire hose that could withstand damages caused by abrasion, wear and tear, while also delivering a flexible and high-quality solution in demanding situations.

Explore Guardman

Guardman - Red

Guardman - Yellow

Guardman - Blue

Guardman - Red

Guardman - Yellow

Guardman - Blue

Product Specifications

Primary Uses & Applications

- Construction

- Fire brigade

- Industrial safety

- Oil and gas

- Refineries

- Airport fire protection

- Military

- Ideal for polar conditions down to –30C

Color Options

- Red (standard)

- Blue (optional)

- Yellow (optional)

- Green (optional)

In Compliance With

- NS 4016/18

- BS6391

- DIN14811

- NEN2242

- BUREA VERITAS Rules for the Classification of Steel Ships

- SOLAS 74 Convention as amended, Regulation II-2/10, X/3

- IMO Res. MSC.36(63)-(1994 HSC Code) as amended, 7

- IMO Res. MSC.97(73)-(2000 HSC Code) as amended, 7

- EN14540:2014

Lengths and Diameters

We offer a range of diameters and lengths for this hose, depending on the version. The diameters range from 38mm to 150mm, and for some diameters the hose can be delivered in lengths up to 200m.

Operating Temperature

The hose has been developed to perform in different weather and environments, with a operating temperature from -30°C to +75°C ( -22°F to +167°F). Intermittent use up to +80°C (+176°F).

Guardman

| INNER DIAMETER | WALL THICKNESS | WEIGHT | BURST PRESSURE | TENSILE STRENGTH | |||||

| Inch | mm | Inch | mm | Lbs / Ft | Kg / m | psi | Bar | x 1000 Lbs | Tons |

| 1 | 26.0 + 1.0 | 0.09 | 2.3 | 0.17 | 0.26 | 1300 | 90 | 5.0 | 2.3 |

| 1 1/2 | 38.0 + 1.6 | 0.09 | 2.3 | 0.23 | 0.34 | 940 | 65 | 6.4 | 2.9 |

| 1 2/3 | 42.0 + 1.6 | 0.09 | 2.3 | 0.23 | 0.34 | 940 | 65 | 6.8 | 3.1 |

| 1 3/4 | 45.0 + 1.6 | 0.09 | 2.3 | 0.24 | 0.35 | 725 | 50 | 7.2 | 3.3 |

| 2 | 51.0 + 2.0 | 0.10 | 2.4 | 0.30 | 0.44 | 690 | 48 | 8.3 | 3.8 |

| 2 1/2 | 65.0 + 2.0 | 0.10 | 2.4 | 0.39 | 0.58 | 690 | 48 | 11.0 | 5.0 |

| 3 | 76.0 + 2.0 | 0.10 | 2.5 | 0.49 | 0.73 | 680 | 47 | 15.4 | 7.0 |

| 4 | 102.0 + 2.5 | 0.11 | 2.8 | 0.74 | 1.10 | 600 | 42 | 21.0 | 9.5 |

| 6 | 151.0 + 2.0 | 0.13 | 3.3 | 1.24 | 1.85 | 505 | 35 | 35.5 | 16.1 |

Note: Minimum safety factor burst to maximum working pressure is 3:1 for non-hazardous/non-flammable liquids. For questions about chemical resistance please check mandals.com/support.

Firefighting Catalog

Want more in-depth knowledge about our lay-flat hoses for firefighting and heavy-duty firefighting? Well, we got you covered in our firefighting catalog.

Let's Talk About Guardman

Our dedicated Sales Managers are ready to cater to your needs and find proper solutions for your business.

Regardless of where you are in the world – we got you covered. Get in touch today.

Stig Seglem

Sales Manager - Asia, Oceania & Middle East

Global Sales Manager - Pipe Rehabilitation

+47 38 27 24 00

[email protected]

Address

Nordre Banegate 26,

4515 Mandal,

Norway